The High Temperature 3D Printing Plastics Market: Revolutionizing Manufacturing with Superior Materials

The high

temperature 3D printing plastics market is experiencing unprecedented

growth, driven by increasing demand for advanced materials capable of

withstanding extreme conditions. The global high temperature 3D printing

plastics market size was valued at USD 795.15 million in 2023 and is projected

to grow at a CAGR of 13.3% from 2024 to 2030, demonstrating the strong momentum

behind this specialized segment of additive manufacturing.

Explore the full report on - https://futuremarketanalytics.com/report/high-temperature-3d-printing-plastics-market/

What Are High Temperature 3D Printing Plastics?

High temperature 3D printing plastics are specialized

materials engineered to maintain their structural integrity and performance

characteristics at elevated temperatures, often exceeding 200°C during

processing and maintaining functionality at operating temperatures well above

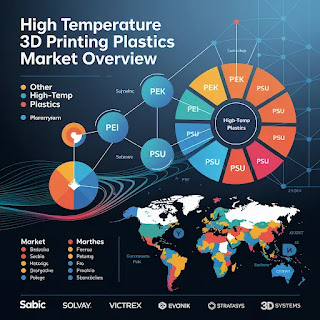

conventional thermoplastics. The most prominent materials in this category

include polyetheretherketone (PEEK), polyetherimide (PEI, commonly known as

ULTEM), and polyphenylsulfone (PPSU).

Known for its exceptional thermal stability, mechanical

properties, and chemical resistance, PEEK is often the material of choice in

industries like aerospace, automotive, and medical. These materials require

specialized high-temperature 3D printers equipped with heated chambers and

advanced extruder systems capable of reaching processing temperatures of 400°C

or higher.

Market Drivers and Growth Factors

The remarkable growth trajectory of the high temperature 3D

printing plastics market stems from several key factors. The aerospace industry

leads demand, where weight reduction and performance under extreme conditions

are critical. The properties of ULTEM 9085 make it an ideal for aerospace and

automotive applications, providing high-performance parts and a lightweight

alternative to metal.

The automotive sector is another major driver, as

manufacturers seek to replace traditional metal components with lighter,

corrosion-resistant alternatives that can withstand engine compartment

temperatures. Medical applications are also expanding rapidly, particularly for

surgical instruments and implantable devices where biocompatibility and

sterilization resistance are essential.

Industrial manufacturing increasingly recognizes the value

of producing end-use parts directly through additive manufacturing, eliminating

traditional tooling requirements and enabling complex geometries impossible

with conventional manufacturing methods.

Key Applications and Industries

PEEK typical applications include elements of machines and

devices in automotive, marine, nuclear, oil-well, electronics, medical, and

aerospace industries. The versatility of high temperature plastics extends

across numerous sectors, each leveraging unique material properties.

In aerospace, these materials produce lightweight interior

components, ductwork, and electrical enclosures that must withstand cabin

pressurization cycles and temperature extremes. The automotive industry

utilizes them for under-hood applications, fuel system components, and

lightweight structural elements that contribute to improved fuel efficiency.

The medical sector benefits from the biocompatibility and

sterilization resistance of materials like PEEK, enabling production of custom

implants, surgical instruments, and diagnostic equipment components. Oil and

gas applications leverage their chemical resistance and high-temperature

performance for downhole tools and pipeline components.

Technological Advancements and Equipment

The success of high temperature 3D printing depends heavily

on specialized equipment capable of handling the extreme processing

requirements. PEEK and PEI materials resist heat, water, pressure, and more but

require a PEEK and PEI 3D printer that generates a high degree of heat to be

used properly.

Modern high-temperature 3D printers feature heated chambers

maintaining ambient temperatures of 200°C or higher, advanced extruder systems

reaching 450°C, and precise temperature control throughout the build volume.

These machines bridge the gap between desktop prototyping systems and full

industrial manufacturing equipment.

Market Challenges and Future Outlook

Despite strong growth prospects, the high temperature 3D

printing plastics market faces several challenges. Material costs remain

significantly higher than conventional 3D printing filaments, and the

specialized equipment required represents substantial capital investment.

Technical expertise requirements for successful processing also limit adoption

among smaller manufacturers.

However, ongoing research into material formulations and

processing techniques continues to address these barriers. New polymer blends

are being developed to improve printability while maintaining high-performance

characteristics, and equipment manufacturers are working to reduce system

complexity and costs.

The market outlook remains highly positive, with expanding

applications across traditional industries and emerging sectors recognizing the

unique advantages of high temperature additive manufacturing. As material costs

decrease and processing technology advances, adoption is expected to accelerate

significantly over the next decade, positioning high temperature 3D printing

plastics as a cornerstone of advanced manufacturing strategies.

Comments

Post a Comment