The Biocompatible 3D Printing Materials Market: Revolutionizing Healthcare Manufacturing

The intersection of 3D printing technology and healthcare

has created one of the most promising markets in additive manufacturing: biocompatible

3D printing materials. This rapidly evolving sector is transforming how

medical devices, dental appliances, and surgical tools are designed and

manufactured, offering unprecedented customization and precision for patient

care.

Explore the full report - https://futuremarketanalytics.com/report/biocompatible-3d-printing-materials-market/

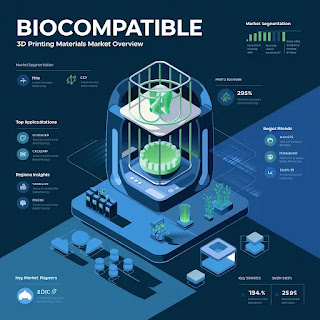

Market Growth and Size

The biocompatible 3D printing materials market is

experiencing remarkable growth, driven by increasing demand in healthcare

settings. Current market valuations show significant momentum, with the global

market size estimated at USD 664.7 million in 2024 and projected to grow at a

compound annual growth rate (CAGR) of 14.6% through 2030. Some analysts project

even more aggressive growth, with forecasts suggesting the market could reach

between USD 1.75 billion and USD 3.5 billion by the early 2030s, depending on

technological adoption rates and regulatory approvals.

The North American market leads this expansion, with the

United States alone accounting for USD 362 million in 2024. This dominance

reflects the region's advanced healthcare infrastructure, aging population, and

early adoption of innovative medical technologies.

Key Applications Driving Demand

Biocompatible 3D printing materials serve diverse

applications across the healthcare spectrum. In the medical field, these

materials are essential for creating custom prosthetics, orthopedic implants,

and surgical guides that require direct patient contact. The dental industry

has emerged as a particularly strong adoption segment, utilizing biocompatible

resins for crowns, bridges, aligners, and surgical templates.

Advanced applications include tissue engineering and

regenerative medicine, where materials must support cell growth and integrate

with biological systems. These cutting-edge uses require materials that are not

only biocompatible but also biodegradable, allowing for gradual absorption as

natural tissue regenerates.

Material Categories and Innovation

The market encompasses several material categories, each

serving specific applications. Polymer-based materials dominate current usage,

offering versatility and cost-effectiveness for applications requiring skin

contact lasting over 30 days or mucosal membrane contact up to 24 hours.

Popular examples include medical-grade resins like MED625FLX, MED610, and

MED620, which provide precise visualization capabilities for medical and dental

applications.

Metal biocompatible materials, particularly titanium and

medical-grade stainless steel, represent the high-value segment of the market.

These materials offer superior strength, durability, and biocompatibility,

making them ideal for permanent implants such as joint replacements, dental

implants, and load-bearing prosthetics. Advanced manufacturing techniques like

direct metal laser sintering (DMLS) have expanded the possibilities for complex

geometries and internal structures previously impossible to achieve through

traditional manufacturing.

Market Drivers and Challenges

Several factors are propelling market growth. The aging

global population creates increasing demand for medical devices and implants.

Personalized medicine trends favor 3D printing's ability to create

patient-specific solutions. Additionally, the technology's capacity to reduce

surgical times, improve patient outcomes, and enable rapid prototyping appeals

to healthcare providers seeking efficiency and innovation.

However, the market faces significant challenges. Stringent

regulatory requirements for medical device approval can slow product

development and market entry. The need for extensive biocompatibility testing

according to standards like ISO 10993 adds complexity and cost to material

development. Additionally, the requirement for specialized sterilization

processes, including ethylene oxide, gamma irradiation, and steam autoclave

methods, demands careful material selection and validation.

Future Outlook

The biocompatible 3D printing materials market stands at the

forefront of healthcare innovation. As material science advances and regulatory

pathways become more established, the market is poised for continued expansion.

Emerging applications in organ printing, drug delivery systems, and smart

implants with integrated sensors represent the next frontier of growth.

The convergence of improved material properties, enhanced 3D

printing technologies, and growing healthcare needs positions this market as a

cornerstone of future medical manufacturing, promising more personalized,

effective, and accessible healthcare solutions worldwide.

Comments

Post a Comment