Revolutionizing Manufacturing: The Rise of Automated 3D Printing

Automated

3D printing is rapidly transforming from a tool for prototyping to a key

technology in mass production. By integrating robotics, artificial intelligence

(AI), and advanced software, automated 3D printing is enabling manufacturers to

achieve faster production, greater precision, and enhanced efficiency. As

industries embrace digital transformation, automated additive manufacturing is

becoming a central pillar of Industry 4.0.

Explore the full report - https://futuremarketanalytics.com/report/automated-3d-printing-market/

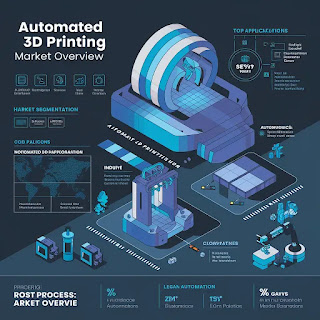

Market Outlook and Growth Potential

The global automated 3D printing market is experiencing

remarkable growth. Industry estimates suggest that the market, valued at just

under $3 billion in 2025, could surpass $13 billion by 2030. This reflects a

compound annual growth rate (CAGR) of over 30%. Such rapid expansion is driven

by rising demand in sectors like automotive, aerospace, healthcare, and

consumer goods, where companies are seeking faster, cost-effective, and more

flexible production processes.

While market forecasts vary, depending on the scope of

technologies and services included (such as hardware, software, and

post-processing automation), the consensus is clear: automated 3D printing is

on a steep upward trajectory globally.

Drivers of Market Growth

Several key factors are fueling the expansion of automated

3D printing:

- Smart

Manufacturing and Industry 4.0 Adoption

Manufacturers are increasingly implementing automation technologies, including robotics and AI, to handle material loading, print monitoring, post-processing, and quality control. This shift reduces human error, increases uptime, and enables 24/7 production. - Demand

Across High-Impact Sectors

- Automotive:

3D printing accelerates prototyping and tool development, enabling faster

design iterations and cost savings.

- Aerospace:

Lightweight components, complex geometries, and part consolidation are

possible through additive manufacturing, reducing assembly time and

weight.

- Healthcare:

Customized implants, dental devices, and surgical tools are produced with

greater accuracy and patient-specific design.

- Sustainability

and Reduced Waste

Additive manufacturing builds parts layer-by-layer, using only the necessary material. This approach minimizes waste compared to traditional subtractive methods, supporting sustainability goals. - Customization

and On-Demand Production

The technology enables cost-effective low-volume production and custom designs, reducing inventory requirements and shortening supply chains.

Challenges in the Market

Despite its advantages, automated 3D printing faces several

hurdles:

- High

Capital Investment: Industrial-scale systems and supporting automation

require substantial upfront costs, making adoption challenging for small

and medium enterprises.

- Material

and Speed Limitations: While improving, the range of printable

materials and overall production speed still lag behind some traditional

manufacturing methods.

- Skilled

Workforce Requirement: Integrating automated 3D printing demands

expertise in CAD design, robotics, and process management, creating a need

for specialized training.

- Regulatory

Compliance: Industries like aerospace and healthcare require rigorous

certification processes for 3D printed parts, which can slow adoption.

Future Opportunities

Looking ahead, innovations are set to unlock new potential:

- Post-Processing

Automation: Robotics for depowdering, cleaning, and surface finishing

are reducing manual labor and improving consistency.

- AI-Enhanced

Quality Control: Real-time monitoring systems are helping detect and

correct defects during the printing process, minimizing waste and ensuring

high quality.

- Distributed

and Swarm Printing: Networked printers or robotic printer swarms offer

scalability and localized production, reducing logistics costs and lead

times.

Global and Regional Momentum

Globally, countries are investing in automated 3D printing

to strengthen manufacturing resilience. For example, India is promoting

additive manufacturing to drive innovation, job creation, and affordable

housing solutions through initiatives supporting startups and industrial

adoption.

Automated 3D printing is no longer just a futuristic

concept—it’s reshaping manufacturing today. As automation technologies advance,

this sector promises smarter, more sustainable, and agile production across

industries. The future of manufacturing is being built layer by layer, and

automated 3D printing is at the heart of this transformation.

Comments

Post a Comment